Soon battery-powered trains could be coming to a station near you.

As the UK’s fleet of diesel engines approaches retirement, manufacturers are looking to replace them with environmentally-friendly alternatives.

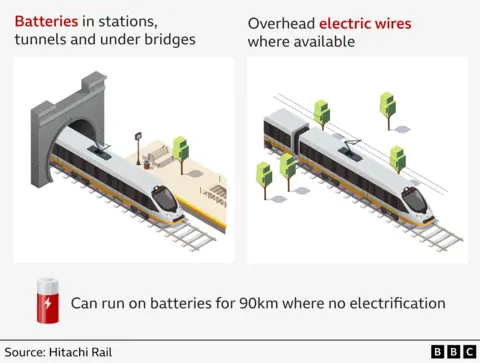

Trains currently draw power from overhead electrified wires or, on lines without these wires, from onboard diesel generators. Many trains are capable of running from both power sources and switch between the two.

Battery-powered trains would save rail operators the cost of installing overhead wires on unelectrified tracks, which are found throughout the UK.

At Hitachi’s factory in Newton Aycliffe, north-east England, testing has just finished on a new “tri-mode” train, in which one diesel generator has been swapped for lithium batteries. This allows it to use up to 50% less fuel when running on lines with no overhead wires.

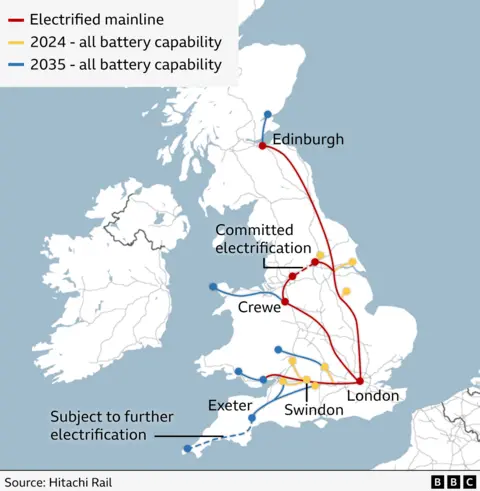

Based on this trial, the company is also planning a train model with no diesel generators at all, which it hopes will be capable of travelling up to 90km (56 miles) on unelectrified stretches of track – with a view to the entire rail network going diesel-free.

Siemens is also developing its own battery-only trains at its factory in Goole, Yorkshire. The company says it is anticipating orders for more than 600 trains from operators including ScotRail, Great Western Railway (GWR) and Transport for Wales. GWR also tested its own battery train earlier this year.

Solely battery-powered trains are already operating in Japan and Germany, but UK experts say they could pose unique fire safety challenges.

Hitachi engineers tell the BBC, though, that it has done extensive testing on the batteries to ensure passengers would be safe in an emergency.

How do battery-powered trains work?

Current diesel-electric trains are designed to draw their power from overhead lines on electrified sections of track. Elsewhere, they use diesel generators housed underneath their carriages.

Hitachi’s new train replaces one of these diesel generator units with 16 batteries, like those found in electric vehicles (EVs).

It says the trains can switch between power sources automatically, and that the tri-mode version would primarily use its batteries in stations and urban areas.

Hitachi says these batteries can recharge while the train is travelling on electrified tracks, or in 10-15 minutes while stationary.

The company says existing diesel-electric trains could also be retrofitted with batteries to save money.

Why now?

The first train to rely solely on batteries went into service in 2016 in Japan – so why are they only now being developed in the UK?

Koji Agatsuma, Hitachi Rail’s technical chief, who oversaw the company’s battery train project, says there is now interest in the UK thanks to a mix of technological improvement and a change in political climate.

He says the new government’s vision is for trains to be “cheaper, greener, more reliable”, while batteries are getting smaller and more powerful.

Yet even now, limitations remain.

Hitachi designed the tri-mode train because its batteries were not yet able to last long enough to cover all sections of unelectrified track in the UK.

More areas of railway can be electrified, but this is costly: in 2020, Network Rail estimated electrification would cost £1m-£2.5m per kilometre of track.

Siemens says to run its battery-powered trains on the UK’s rail network, small sections of track would need to be electrified, and fast-charging points placed along train routes.

Hitachi’s test train was able to travel 70km (44 miles) using its batteries alone. This would work for services between London and Oxford or Hull, due to the amount of electrified rail on these routes, but it would be unable to run the full length of the line between Crewe and Holyhead, for example.

Hitachi Rail

Hitachi Rail

And though it was able to travel 135km (84 miles) using diesel as well as batteries, this was on relatively flat testing track. Routes such as those served by TransPennine – which leant Hitachi the test Class 802 train – have inclines which require more energy, shortening the overall distance it could travel unaided.

Jim Brewin, Hitachi Rail’s UK and Ireland chief, says the government’s aim to cut the country’s carbon dioxide emissions to ‘net zero’ by 2050 means fully battery-powered trains are the direction the industry is moving in, with hybrid trains a stepping stone on the way.

He says that as cells get lighter and more powerful, the company can swap them out for newer models to improve performance. Its recent testing demonstrated existing trains could also be modified to go full or part battery-powered.

Are there safety risks?

Experts in lithium batteries say that, when used in road vehicles, EV batteries are at least 20 times less likely to catch fire than diesel or petrol cars.

Hitachi’s train uses Nissan Leaf cells, which have been involved in 16 fires in the 14 years they have been used in road vehicles, according to EV Fire Safe, which gathers data on battery fires around the world. This is out of more than 500,000 cells that have been sold worldwide.

“Managed properly, lithium batteries are very safe,” says Jon Simpson, a former firefighter turned fire safety consultant.

But when lithium batteries are corrupted, they can experience thermal runaway – meaning a cell undergoes uncontrollable temperature rises, making a fire hard to control and extinguish.

The kind of “catastrophic event” that could cause something like this would be a crash or a derailment in which a cell is damaged, says Jon Hughes, managing director of UK Fire Training.

But Euan McTurk, a consultant battery electrochemist, says Nissan Leaf cells are “far more robust than people give them credit for”.

For them to catch fire, he says “it would take some spectacular lancing of the actual cells themselves, which would mean going through a very strong external structure”.

Part of Hitachi’s testing was to deliberately destabilise a cell, including piercing it and overheating it, says Chris Dautel, senior electrical engineer at the manufacturer.

He adds that Hitachi has placed a heat shield around each cell to prevent the issue spreading to other cells, meaning “no danger to passengers in [a] case of thermal runaway”.

The train is also fitted with a cooling unit on the roof to regulate the batteries’ temperature, and the company has developed software that monitors and regulates the cells.

The urgent response to a lithium battery fire is to flood the cell with as much water as possible to cool it down, says fire safety consultant Mr Simpson, which may not be viable depending on where the fire occurs.

“Tunnels are probably the riskiest area in a rail environment,” says Graham Kenyon, an electrical engineering consultant. “If you get a fire, probably the worst things to deal with when you’re evacuating people are smoke and fumes, vapours, gases that are toxic.”

In some cases, it is safer for the fire brigade to leave the battery to burn itself out. But leaving a train on the track could pose a major disruption.

Dautel says that a carriage with a battery fire could still be moved out of the way, even while burning, such was the effectiveness of the fire barrier around the cells.

“In the case of incidents, we would evacuate the passengers, but they wouldn’t see anything,” he says.

As each unit operates independently, he adds, the train would still be able to move itself using batteries on other carriages – or be pulled by another train.